Versatile Servo System

Versatile Servo System

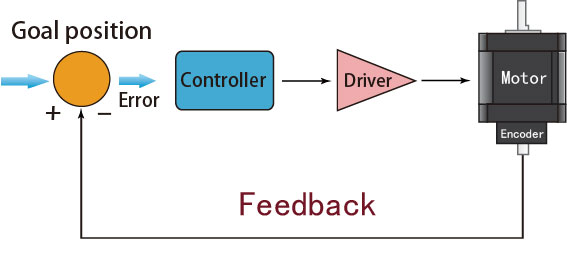

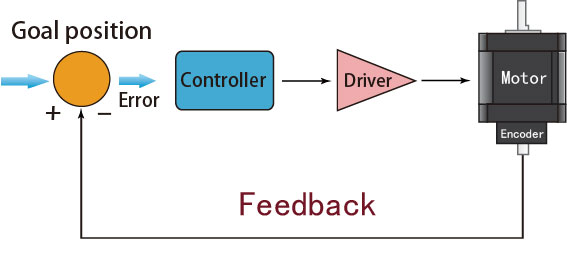

T-Servo, which is developed by SMMC, many engineers at home and overseas, and Japanese manufacturer, is a closed-loop stepper servo system with advantages such like various torque controls and high-precision positioning. Unlike usually servo motors, users can easily switch control modes with less motor hunting by using T-Servo.

T-SERVO

T-Servo, which is developed by SMMC, many engineers at home and overseas, and Japanese manufacturer, is a closed-loop stepper servo system with advantages such like various torque controls and high-precision positioning. Unlike usually servo motors, users can easily switch control modes with less motor hunting by using T-Servo.

Production information

T-Servo, which is developed by SMMC, many engineers at home and overseas, and Japanese manufacturer, is aclosed-loop stepper servo system with advantages such like various torque controls and high-precision positioning.

Unlike usually servo motors, users can easily switch control modes with less motor hunting by using T-Servo.

Position control can be freely switched to: Servo mode / Dual mode / Stepping mode / Stepping closed loop mode.

With the motors equipped with high resolution optical encoder, customers can choose the most suitable mode fortheir applications! Under Dual mode, the control method would be switched from closed loop to open loop so thatthe motor could stop without hunting. Therefore, the settling time can be reduced, and the production process canbe shortened. Also, Output Compare function is available with up to 990 times / sec output, and suitable forapplying in line-scan devices.

4 modes, 3 methods. A multi-purpose machine!

4 modes, 3 methods. A multi-purpose machine!

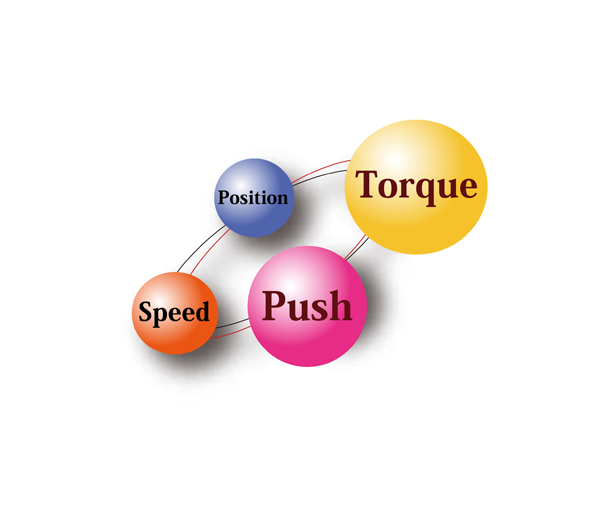

There are four drive modes ( ① position control ② torque control ③ speed control ④ Push control) and

Three control methods ( ① I/O ② external pulse input (CW / CCW, PUL / DIR) ③ RS485/RS232 communication,

Modbus ASCII / RTU protocols are supported when it is connected to a PC / HMI to achieve multi-axis control.

Three control methods ( ① I/O ② external pulse input (CW / CCW, PUL / DIR) ③ RS485/RS232 communication,

Modbus ASCII / RTU protocols are supported when it is connected to a PC / HMI to achieve multi-axis control.

Product Features

Low heat generation & energy-saving

Low heat generation & energy-savingHigh-efficient operations due to the most appropriate current adjustment according to loads.

High precision positioning

High precision positioningHigh precision positioning can be realized by assembling high resolution ( 6400 / 9600 / 12800 / 16000 ppr ) optical encoder.

Fast response

Fast responseThe maximum instant torque is 150% of rated torque. As the result, the motor moves smartly.

High speed & high torque

High speed & high torqueA new Smart algorithm was developed to realize the purpose of high speed and high torque.

Highly reliable system

Highly reliable systemT-Servo is a closed-loop stepper servo system by assembling the optical encoder, so no step-out occurs.

Numbering System

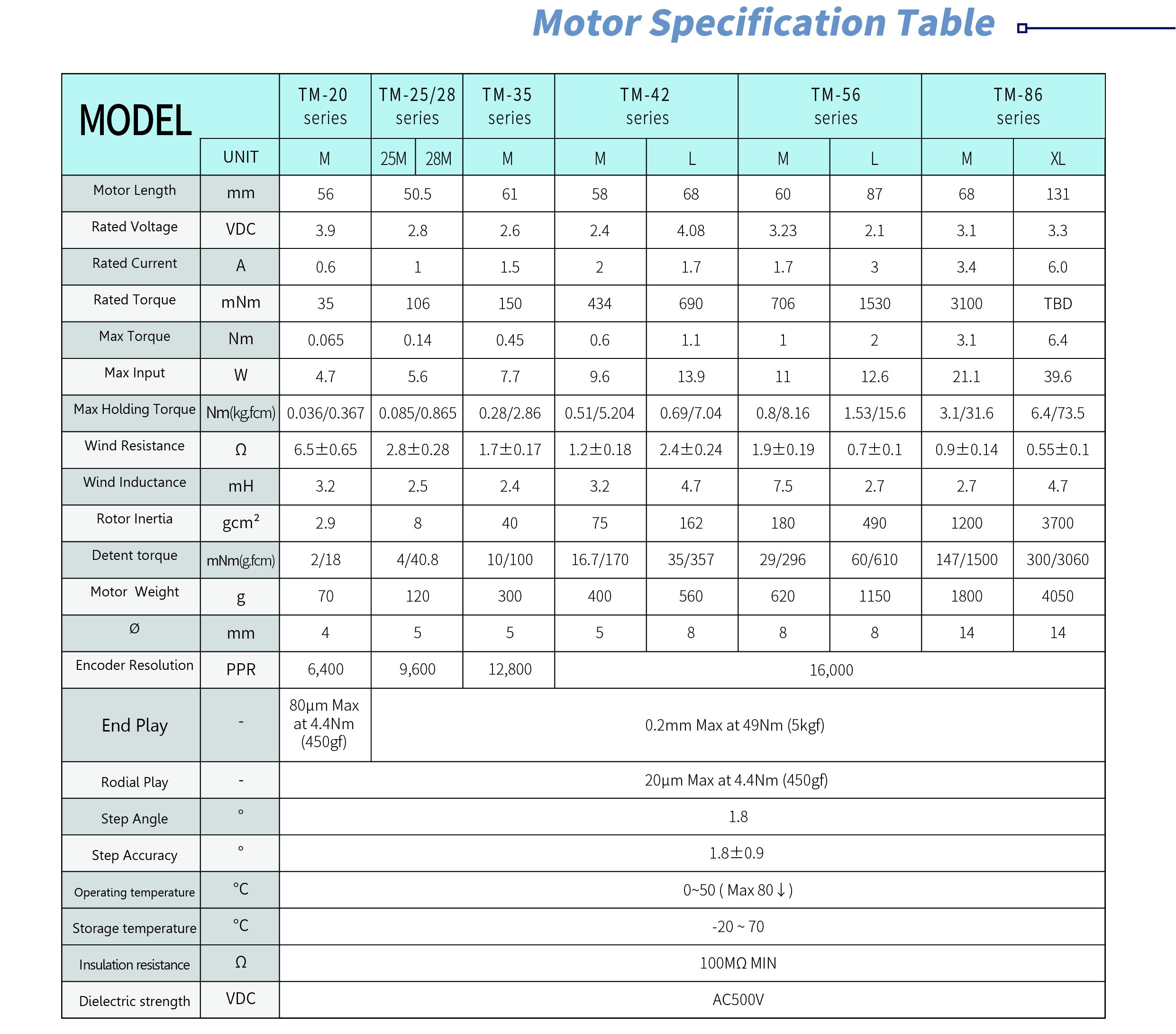

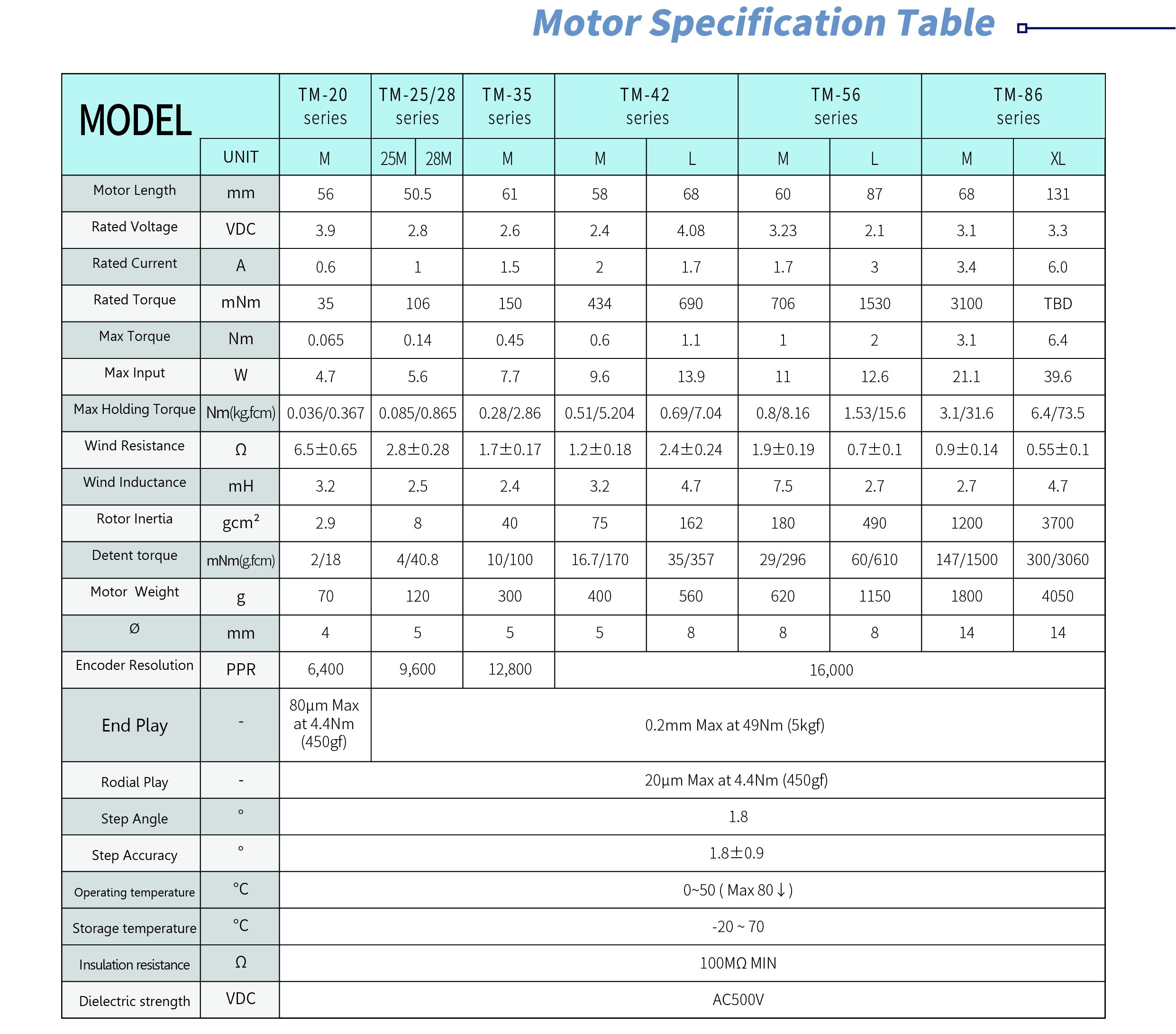

Motor Specification Table

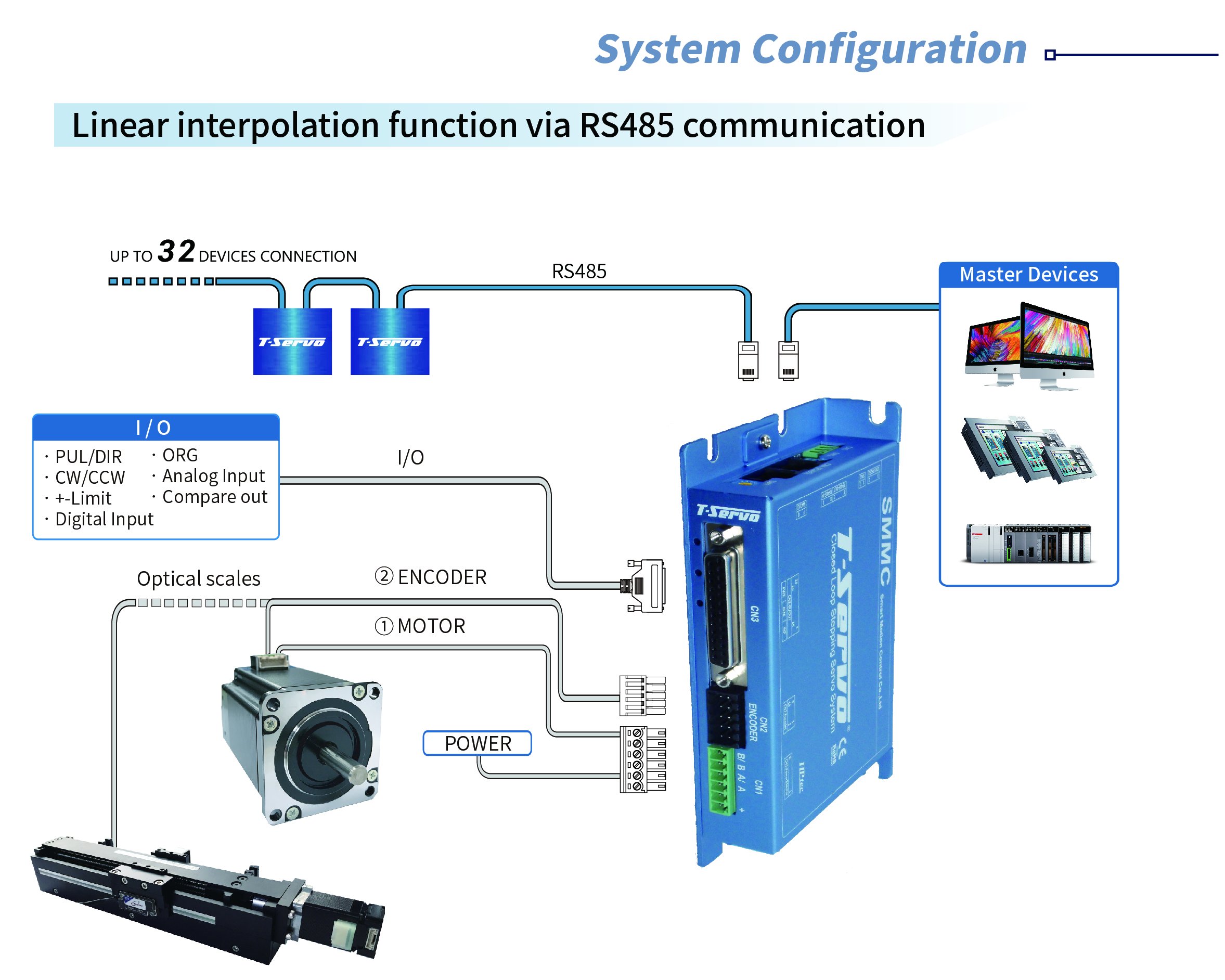

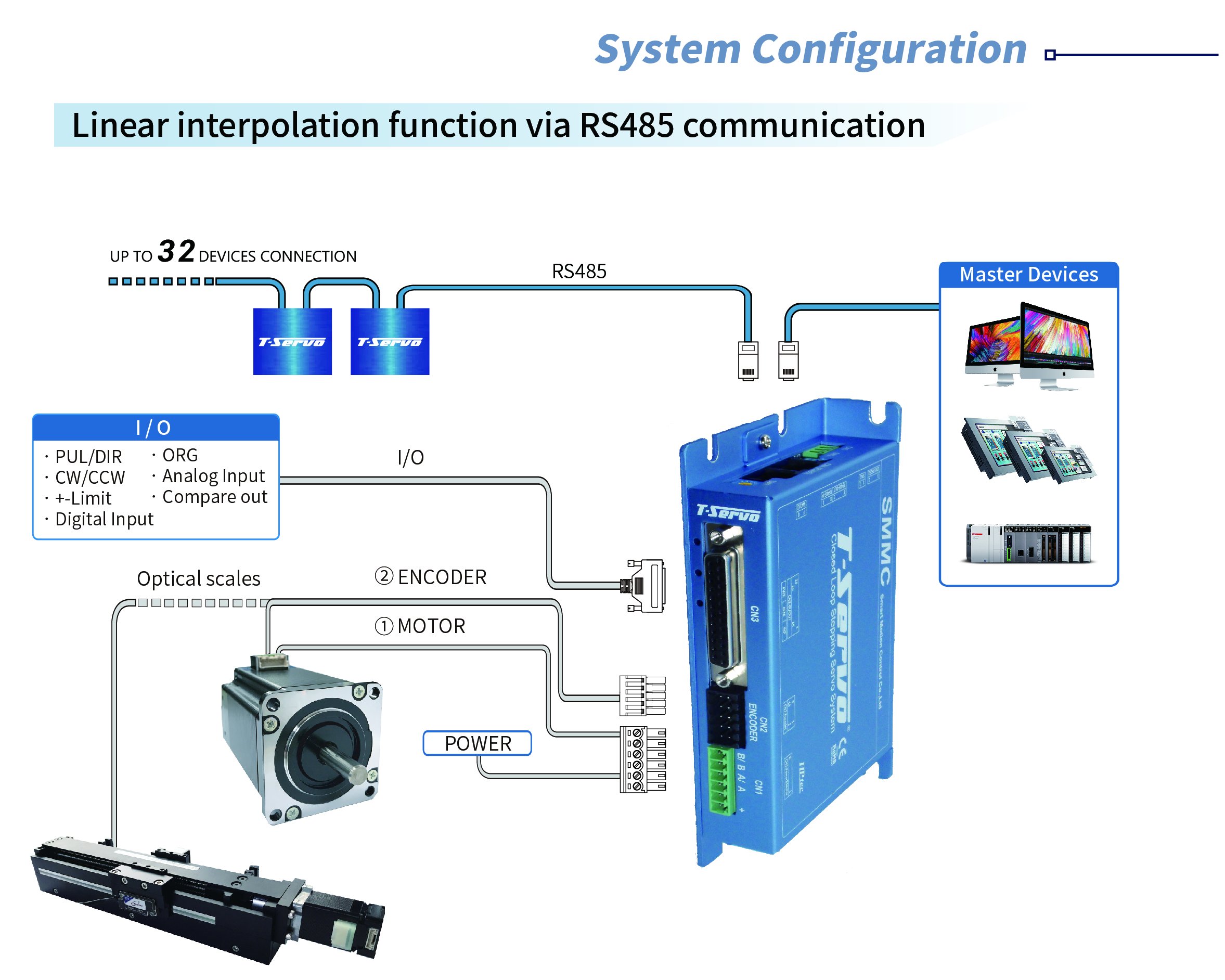

System Configuration

※ Linear interpolation function via RS485 communication

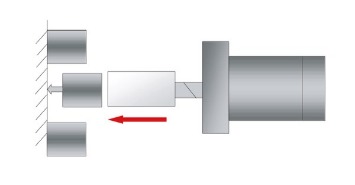

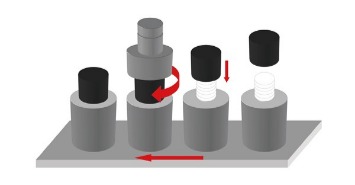

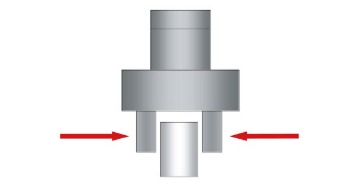

Push control / Soft landing

A pressing motion like the air cylinder can be performed by adding torque limit. Push torque is adjustable.With T-Servo, users also can keep the same position and torque in situ during push control.

• Component alignment

• Connectors manufacturing

• Pressing process

• Connectors manufacturing

• Pressing process

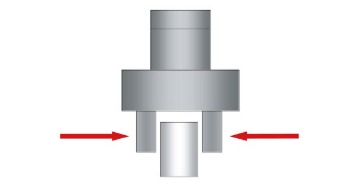

Gripping / Measurement / Sorting

Gripping/Gripper application with specified force is possible by using T-servo. Furthermore, by recording the gripping positions, T-servo is capable of driving the gripper to to sizes measurement/object sorting.

• Pick & place applications

• Outer/inner diameter Measurement

• Product sorting

• Outer/inner diameter Measurement

• Product sorting

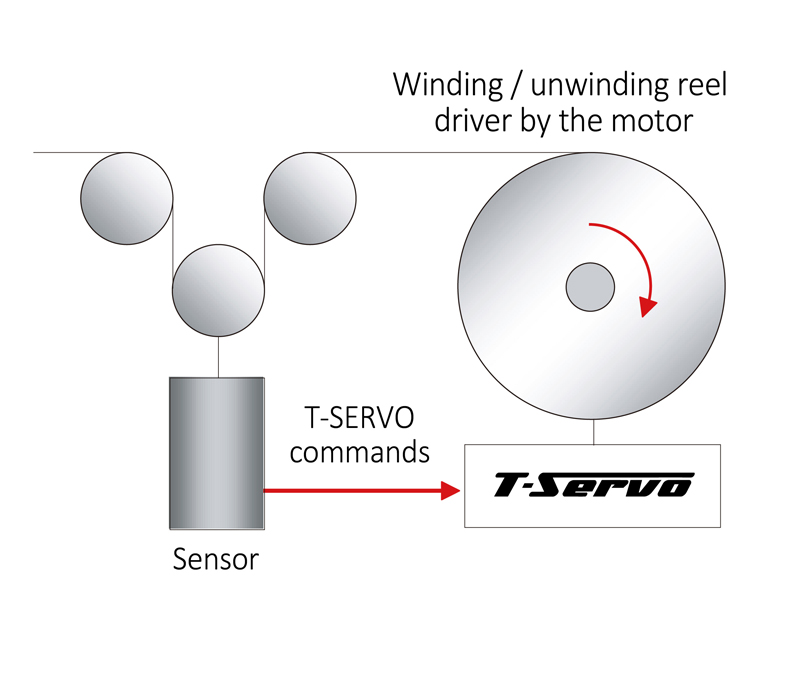

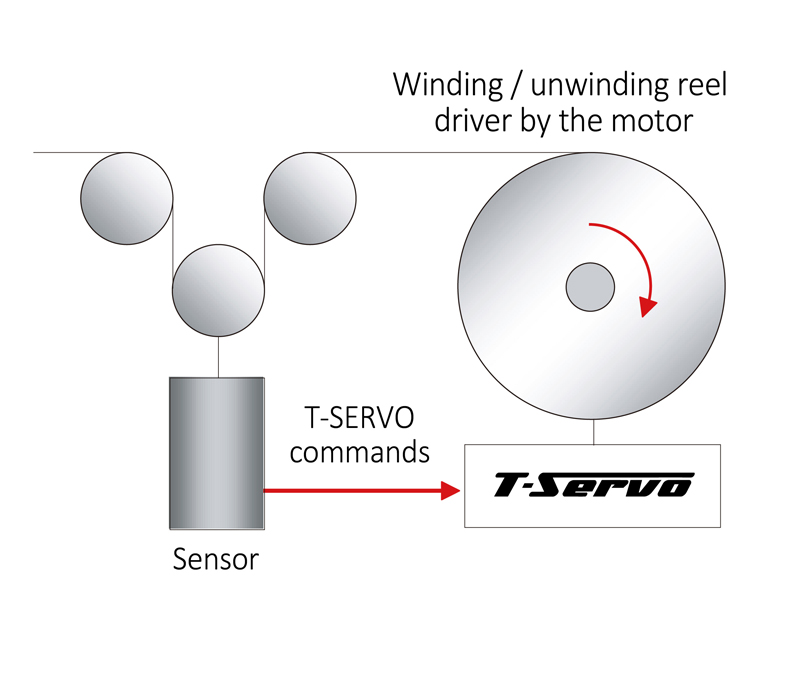

Torque (Tension) control

Torque/Tension control can be achieved with internal programming or external analog commands.

• Winder/Rewinders

• Unwinders

• Tension reel applications

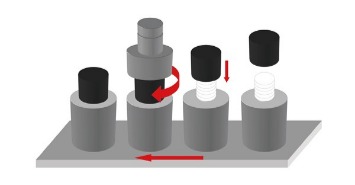

Automatic screw fastening / capping machines

Torque/Tension control can be achieved with internal programming or external analog commands.

• Screw driving

• Bottle capping

HMI & Touch text panel are also available.

【Power Supply】

Applicable in situations such as high acceleration / deceleration is needed or back EMF is generated.

Applicable in situations such as high acceleration / deceleration is needed or back EMF is generated.

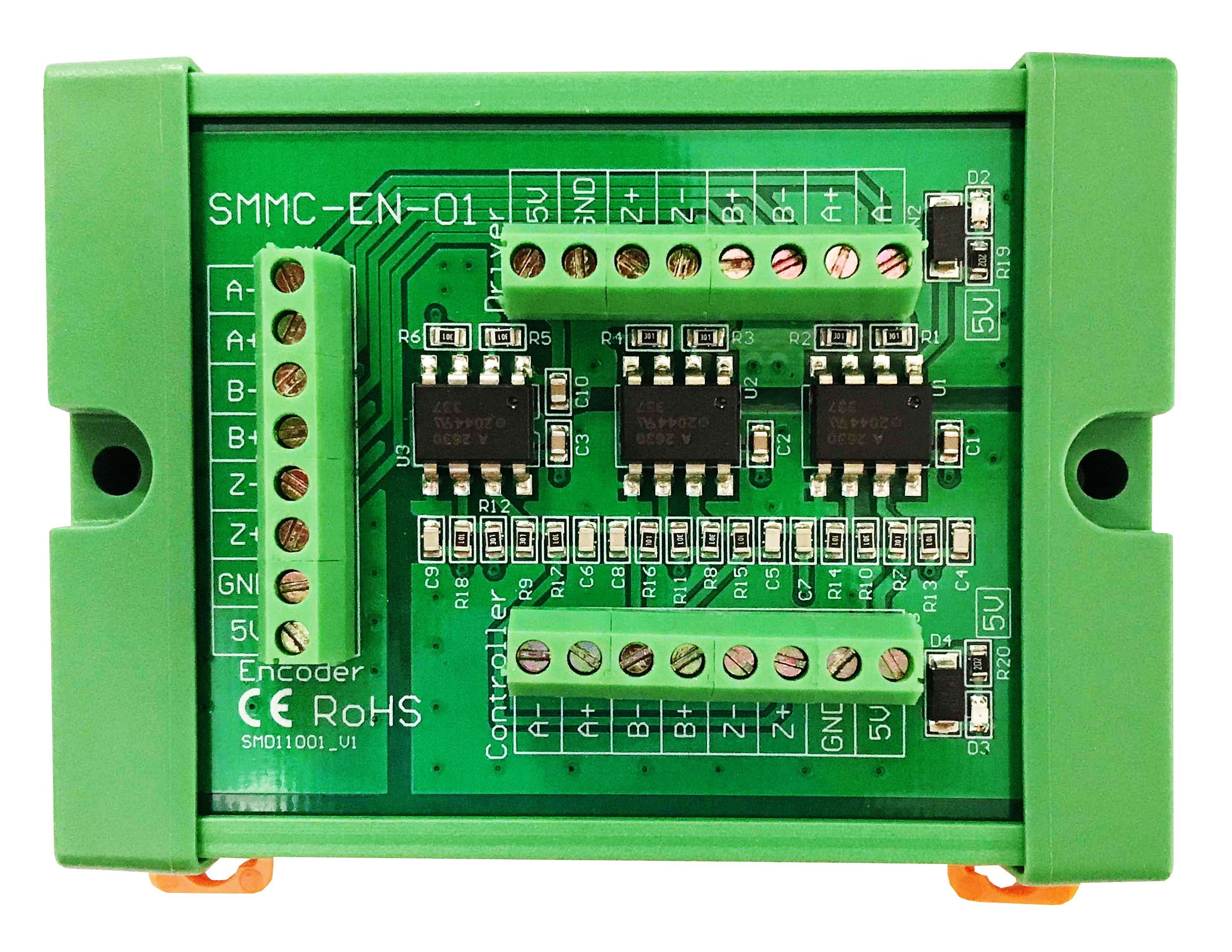

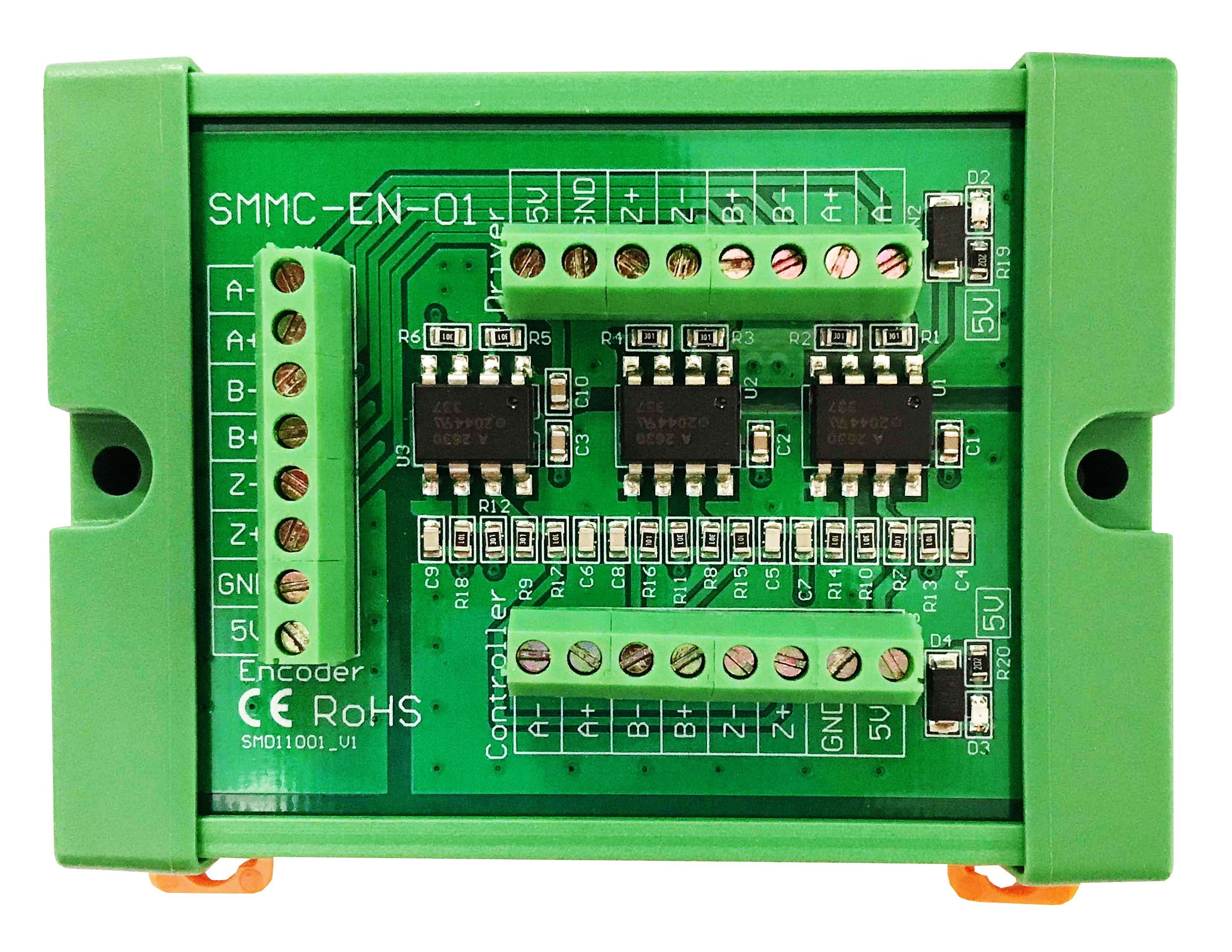

Junction board for encoders

【SMMC-EN-01】

Applicable for incremental encoders & line driver output supported

Signal converter

【SM-891】

Highly compatible or High compatibility compatible with WINXP, 7,8,10,11

Feature

4 modes, 3 methods. A multi-purpose machine!

4 modes, 3 methods. A multi-purpose machine!

There are four drive modes ( ① position control ② torque control ③ speed control ④ Push control) and

Three control methods ( ① I/O ② external pulse input (CW / CCW, PUL / DIR) ③ RS485/RS232 communication,

Modbus ASCII / RTU protocols are supported when it is connected to a PC / HMI to achieve multi-axis control.

Three control methods ( ① I/O ② external pulse input (CW / CCW, PUL / DIR) ③ RS485/RS232 communication,

Modbus ASCII / RTU protocols are supported when it is connected to a PC / HMI to achieve multi-axis control.

Product Features

Low heat generation & energy-saving

Low heat generation & energy-savingHigh-efficient operations due to the most appropriate current adjustment according to loads.

High precision positioning

High precision positioningHigh precision positioning can be realized by assembling high resolution ( 6400 / 9600 / 12800 / 16000 ppr ) optical encoder.

Fast response

Fast responseThe maximum instant torque is 150% of rated torque. As the result, the motor moves smartly.

High speed & high torque

High speed & high torqueA new Smart algorithm was developed to realize the purpose of high speed and high torque.

Highly reliable system

Highly reliable systemT-Servo is a closed-loop stepper servo system by assembling the optical encoder, so no step-out occurs.

Specification

Numbering System

Motor Specification Table

System Configuration

※ Linear interpolation function via RS485 communication

Application

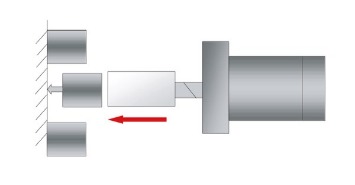

Push control / Soft landing

A pressing motion like the air cylinder can be performed by adding torque limit. Push torque is adjustable.With T-Servo, users also can keep the same position and torque in situ during push control.

• Component alignment

• Connectors manufacturing

• Pressing process

• Connectors manufacturing

• Pressing process

Gripping / Measurement / Sorting

Gripping/Gripper application with specified force is possible by using T-servo. Furthermore, by recording the gripping positions, T-servo is capable of driving the gripper to to sizes measurement/object sorting.

• Pick & place applications

• Outer/inner diameter Measurement

• Product sorting

• Outer/inner diameter Measurement

• Product sorting

Torque (Tension) control

Torque/Tension control can be achieved with internal programming or external analog commands.

• Winder/Rewinders

• Unwinders

• Tension reel applications

Automatic screw fastening / capping machines

Torque/Tension control can be achieved with internal programming or external analog commands.

• Screw driving

• Bottle capping

Optional Fittings

HMI & Touch text panel are also available.

【Power Supply】

Applicable in situations such as high acceleration / deceleration is needed or back EMF is generated.

Applicable in situations such as high acceleration / deceleration is needed or back EMF is generated.

Junction board for encoders

【SMMC-EN-01】

Applicable for incremental encoders & line driver output supported

Signal converter

【SM-891】

Highly compatible or High compatibility compatible with WINXP, 7,8,10,11